The Mechanical Engineering Department was established in 2001. It aims to provide students with the knowledge and skills necessary to excel in the field of mechanical engineering. This branch of engineering deals with the design, analysis, manufacturing, and maintenance of mechanical systems. The department's faculty members are experienced professionals with diverse backgrounds, including industry and academia. They are responsible for delivering lectures, conducting research, and guiding students in their academic pursuits. Many faculty members engage in research projects, which not only advance knowledge in the field but also provide opportunities for students to participate in cutting-edge research. The department invites industry experts as guest speakers to share their experiences and provide insights into the latest developments in mechanical engineering. Every year, the department organizes workshops, industrial visits, internships, and symposiums to keep students updated with the latest trends and upcoming technological developments.

The vision of the department is to impart quality technical education for promoting centre of excellence in core field through which the professional experts can be produced in order to carter the needs of the industry.

To develop the problem solving and analytical skill of the students in the field of Mechanical Engineering with a sound knowledge of basic science and Engineering.

To create an arena that encourages exploration, curiosity and creativity of the Students to become an intensive researcher in their domain.

To impart the qualities among the students to become a successful team player, Leader and professional challenger in the area of Entrepreneurship.

To inculcate the virtue of social responsibility and professional ethics.

To motivate the students towards solving problems related to design, analysis and implementation of mechanical systems.

As the Head of the Mechanical Engineering Department, Our department has always been a beacon of innovation and practical learning, and it is your relentless pursuit of knowledge and your passion for engineering that makes this possible. Your efforts and achievements have not only raised the bar for academic excellence but have also significantly contributed to making our department one of the most respected in the institution. As we continue to navigate through these challenging times, I want to assure you that our commitment to providing a world-class education and research environment remains unwavering. We will continue to support each one of you in your academic journey, ensuring that you have the necessary resources and opportunities to succeed. Let us continue to strive for excellence, uphold the highest standards of integrity and professionalism, and work together to further enhance the reputation of our esteemed department.

| S.No. | Name of the Faculty Member | Qualification | Designation |

|---|---|---|---|

| 1 | Dr. S. Harikrishnan | M.E., Ph.D. | HOD & Professor |

| 2 | Dr. S. Babu Sasikumar | M.E., Ph.D. | Associate Professor |

| 3 | Dr. C. Sadhasivam | M.E., Ph.D. | Associate Professor |

| 4 | Dr. J. Pradeep Kumar | M.Tech., Ph.D. | Assistant Professor |

| 5 | Mr. Immanuel Sam Franklin | M.Tech., Ph.D. | Associate Professor |

| 6 | Mr. Vigneshwaran | M.E., Ph.D. | Assistant Professor |

| 7 | Mr. K. Chinna Durai | M.E., Ph.D. | Assistant Professor |

| 8 | Mr. J. Joel Jobes | M.E. | Assistant Professor |

| 9 | Dr. R. Charles Godwin | M.Tech., Ph.D. | Assistant Professor |

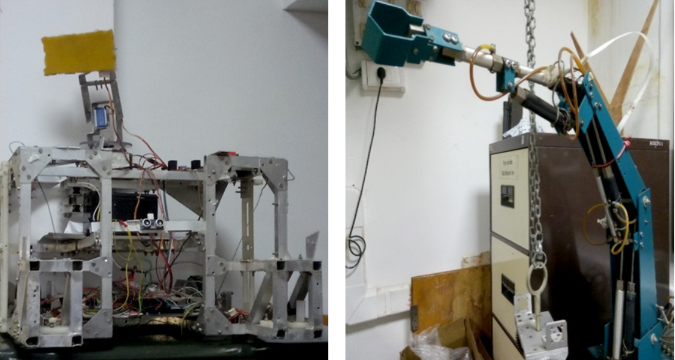

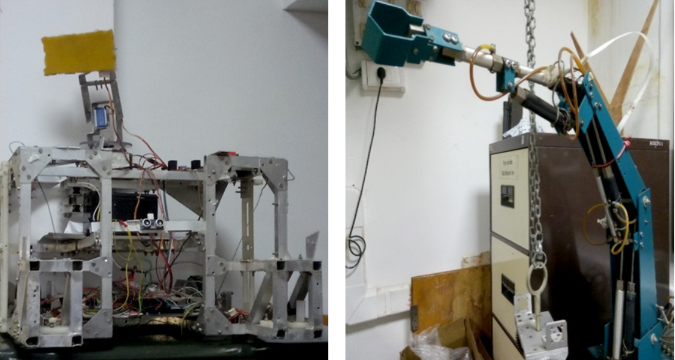

Creative Projects

Funded Projects

Publication by the Faculty in Referred Journals

| S.No. | Facility | Count | Total Area in Sq.m |

|---|---|---|---|

| 1 | Class Rooms | 3 | 235 |

| 2 | Tutorial Room | 1 | 80 |

| 3 | Labs | 6 | 765 |

| 4 | Smart Class Rooms | 3 | 235 |

| 5 | Auditorium / Seminar hall | 1 | 102 |

| 6 | Video Conferencing Room | 1 | 1 |

| 7 | Workshop | 1 | 263 |

| 8 | Drawing Hall | 2 | 1094 |

| 9 | Research Lab | 1 | 1 |

| 10 | HOD's Cabin | 1 | 19 |

| 11 | Department Library | 1 | 40 |

| 12 | Faculty Cabin | 14 | 42 |

| 13 | Counseling Room | 1 | 19 |

| S.No | Date | Workshops & Conferences |

|---|---|---|

| 1 | 24/8/2019 | One day workshop on Optimization techniques |

| 2 | 11/1/2019 | Go Karting Championship |

| 3 | 16/8/18 | One day workshop on Optimization technique |

| 4 | 28/5/18 | Faculty development programme on Design of machine elements |

| 5 | 2/3/18 | Kings Moto Championship |

| 6 | 20/11/17 | Faculty development programme on Thermal Engineering |

| 7 | 22/9/17 | National level workshop on Lean Six Sigma |

| 8 | 24/8/17 | One day workshop on Optimization technique |

| 9 | 25/10/17 | Two day workshop on Autodesk 360 Fusion |

| 10 | 23/2/18 | One day workshop on Frame design and motion analysis |

| 11 | 15/9/16 | Guest lecture: Engineers day |

| 12 | 17/8/16 | One day workshop on Optimization technique |

| 13 | 3/9/16 | Guest lecture: Advance Industrial process |

| 14 | 13/8/16 | ISME student chapter Inauguration and Guest lecture on Advance processes in India |

| 15 | 5/8/15 | One day carrier oriented workshop on hands-on training in NDT |

| 16 | 8/3/16 | Guest Lecture on Recent trends in Manufacturing |

| 17 | 12/8/14 | Hands on Training using Mini Tab Software |

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Delphi TVS

2.04 LPA

Delphi TVS

Delphi TVS

2.04 LPA

Delphi TVS

Industrial Metrological Centre

2.5 LPA

Industrial Metrological Centre

Industrial Metrological Centre

2.5 LPA

Industrial Metrological Centre

Preludesys.

3.60 PA

Preludesys.

Sutherland

2.16 LPA

Sutherland

Joy Technology

1.92 LPA

Joy Technology

National Plastic Technology

1.2 LPA

National Plastic Technology

National Plastic Technology

1.2 LPA

National Plastic Technology

National Plastic Technology

1.2 LPA

National Plastic Technology

Q Spider

2.52 LPA

Q Spider

Our Recruiters

|  |  |

|  |  |

|  |  |

|  |

| Faculty Name | Research Title | Year | ISSN/DOI |

|---|---|---|---|

| Dr.Harikrishnan | Experimental investigation of parallel type - evacuated tube solar collector using nanofluids, Taylor and Francis,ENERGY SOURCES, PART A: RECOVERY, UTILIZATION, AND ENVIRONMENTAL EFFECTS | 2020-21 | Online ISSN: 1556-7230 |

| Dr. BabuSasi Kumar | Experimental investigation of parallel type - evacuated tube solar collector using nanofluids, Taylor and Francis,ENERGY SOURCES, PART A: RECOVERY, UTILIZATION, AND ENVIRONMENTAL EFFECTS | 2020-21 | Online ISSN: 1556-7230 |

| T.Kanagaraju | Effect of cryogenic and wet coolant performance on drilling of super duplex stainless steel (2507) | 2020-21 | doi:10.1166/mex.2019.1613 |

| Mr.K.Nimel Ross | Investigation of surface modification and tool wear on milling Nimonic 80A under hybrid lubrication is published in Tribology International. (Elsevier-IF- 4.27), 2020 | 2020 - 21 | |

| Applying visualization techniques to study the fluid flow pattern and the particle distribution in the casting of metal matrix composites” is published in Journal of Manufacturing Processes. (Elsevier-IF- 4.17), 2020 | 2020 - 21 | ||

| Machining Investigation of Nimonic‑80A Superalloy Under Cryogenic CO2 as Coolant Using PVD‑TiAlN/TiN Coated Tool at 45° Nozzle Angle” published in Arabian journal of science and Engineering. (Springer-IF- 1.72), 2020 | 2020 - 21 | ||

| Multi-response optimization of Ti-6Al-4V milling using AlCrN/TiAlN coated tool under cryogenic cooling” published in Journal of production systems and Manufacturing sciences. (Imperial Open), 2020 | 2020 - 21 | ||

| Experimental investigation of Mechanical properties in friction welding parameters for dis-similar metals (SS-304 & SS-410)” published in Materials today Proceedings. (Elsevier), 2020 | 2020 - 21 |

| Faculty Name | Book/Journal Title | Research Chapter/Topic | Institution | Publisher |

|---|---|---|---|---|

| Dr.S.Harikrishnan | Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications | Nanomaterials for Latent Thermal Energy Storage | Springer | |

| Dr.S.Harikrishnan | Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications | Nanomaterials for Latent Thermal Energy Storage | Springer | |

| Dr. Muniaraj | EFFECT OF CUTTING PARAMETERS ON | Kings Engineering College | Elsevier | |

| Dr. Muniaraj | SURFACE ROUGHNESS IN DRILLING OF | Kings Engineering College | Elsevier | |

| Dr. Muniaraj | AL-SIC-GR COMPOSITES USING RSM AND | Kings Engineering College | Elsevier | |

| Dr. Muniaraj | FUZZYLOGIC MODELING METHOD | Kings Engineering College | Elsevier |

| S.No | Company Name | Address | Date/Year of Signing MOU | Duration |

|---|---|---|---|---|

| 1 | AES Automotive Company Private Limited | 27/1-D, Jothi Nagar, Periyapanicherry Road, Paraniputhur, Mangadu Main road,Chennai - 600 122, Tamil Nadu, India | 12 th August 20142014-15 | 2 Years |

| 2 | Arrow Machine Tools | New No.18,Old No.1, Balaji Nagar,Ambattur, Chennai- 600 053, Tamil Nadu, India | 10 th February 20152014-15 | 2 Years |

| 3 | Ceecons Process Technologies Private Limited | SP-66, XVII phase, Ambattur Industrial Estate, Ambattur, Chennai 600 058. Tamil Nadu, India | 15 th October 2014 2014-15 | 3 Years |

| 4 | Design CAD Technologies | No. 3/ 1319, Bharathiyar Nagar, 6th street, O.M.R., Mettukuppam, Chennai-97. | 19th March 2015 2014-15 | 3 Years |

| 5 | Dynatherm Alloys Private Limited | No.7, Kamala Nagar,Sholinganallur, Chennai – 600 119 | 15th March 2017 2016-17 | 2 Years |

| 6 | IP Rings (P)Ltd | D11/12 Industrial Estate, Maraimalai Nagar-603 209, Kancheepuram District,Tamil Nadu, India | 25th April 2017 2016-17 | 2 Years |

| 7 | Kerith Technical Services, | No:72/28, Dr.Moorthy Nagar Main road, Padi, Chennai -600 050, Tamil Nadu, India | 6th June2018 2017-18 | 2 Years |

| 8 | Precision Machines & Auto Components (P) Ltd | No.25 & 26, Mount Poonamallee Road, Nandambakkam, Chennai – 600 089. | 8th August 2018 2017-18 | 2 Years |

| 9 | Trinity Institute of NDT Technology | Trinity NDT 'Aspire', #491, Site No.12,4th Phase, 2nd Stage, Peenya Industrial Area, Bangalore – 560 058, India | 13 th February 2019 2018-19 | 2 Years |

| 10 | TWG Group of Training & Certification | No:6 Boopathy Street, Virugampakam,Chennai – 600 092,Tamil Nadu, India | 15th March 2109 2018-19 | 2 Years |

In our department, there are sophisticated equipment in Manufacturing Technology Lab where, the scholars/researchers could be permitted to utilize the facility. Also, In the department there are potential and competent doctorates working in the fields of Manufacturing, Thermal and Materials Science. They provide fruitful suggestions and guidance to the research scholars.

The Mechanical Engineering Department was established in 2001. It aims to provide students with the knowledge and skills necessary to excel in the field of mechanical engineering. This branch of engineering deals with the design, analysis, manufacturing, and maintenance of mechanical systems. The department's faculty members are experienced professionals with diverse backgrounds, including industry and academia. They are responsible for delivering lectures, conducting research, and guiding students in their academic pursuits. Many faculty members engage in research projects, which not only advance knowledge in the field but also provide opportunities for students to participate in cutting-edge research. The department invites industry experts as guest speakers to share their experiences and provide insights into the latest developments in mechanical engineering. Every year, the department organizes workshops, industrial visits, internships, and symposiums to keep students updated with the latest trends and upcoming technological developments.

The vision of the department is to impart quality technical education for promoting centre of excellence in core field through which the professional experts can be produced in order to carter the needs of the industry.

To develop the problem solving and analytical skill of the students in the field of Mechanical Engineering with a sound knowledge of basic science and Engineering.

To create an arena that encourages exploration, curiosity and creativity of the Students to become an intensive researcher in their domain.

To impart the qualities among the students to become a successful team player, Leader and professional challenger in the area of Entrepreneurship.

To inculcate the virtue of social responsibility and professional ethics.

To motivate the students towards solving problems related to design, analysis and implementation of mechanical systems.

As the Head of the Mechanical Engineering Department, Our department has always been a beacon of innovation and practical learning, and it is your relentless pursuit of knowledge and your passion for engineering that makes this possible. Your efforts and achievements have not only raised the bar for academic excellence but have also significantly contributed to making our department one of the most respected in the institution. As we continue to navigate through these challenging times, I want to assure you that our commitment to providing a world-class education and research environment remains unwavering. We will continue to support each one of you in your academic journey, ensuring that you have the necessary resources and opportunities to succeed. Let us continue to strive for excellence, uphold the highest standards of integrity and professionalism, and work together to further enhance the reputation of our esteemed department.

| S.No. | Name of the Faculty Member | Qualification | Designation |

|---|---|---|---|

| 1 | Dr. S. Harikrishnan | M.E., Ph.D. | HOD & Professor |

| 2 | Dr. S. Babu Sasikumar | M.E., Ph.D. | Associate Professor |

| 3 | Dr. C. Sadhasivam | M.E., Ph.D. | Associate Professor |

| 4 | Dr. J. Pradeep Kumar | M.Tech., Ph.D. | Assistant Professor |

| 5 | Mr. Immanuel Sam Franklin | M.Tech., Ph.D. | Associate Professor |

| 6 | Mr. Vigneshwaran | M.E., Ph.D. | Assistant Professor |

| 7 | Mr. K. Chinna Durai | M.E., Ph.D. | Assistant Professor |

| 8 | Mr. J. Joel Jobes | M.E. | Assistant Professor |

| 9 | Dr. R. Charles Godwin | M.Tech., Ph.D. | Assistant Professor |

Creative Projects

Funded Projects

Publication by the Faculty in Referred Journals

| S.No. | Facility | Count | Total Area in Sq.m |

|---|---|---|---|

| 1 | Class Rooms | 3 | 235 |

| 2 | Tutorial Room | 1 | 80 |

| 3 | Labs | 6 | 765 |

| 4 | Smart Class Rooms | 3 | 235 |

| 5 | Auditorium / Seminar hall | 1 | 102 |

| 6 | Video Conferencing Room | 1 | 1 |

| 7 | Workshop | 1 | 263 |

| 8 | Drawing Hall | 2 | 1094 |

| 9 | Research Lab | 1 | 1 |

| 10 | HOD's Cabin | 1 | 19 |

| 11 | Department Library | 1 | 40 |

| 12 | Faculty Cabin | 14 | 42 |

| 13 | Counseling Room | 1 | 19 |

| S.No | Date | Workshops & Conferences |

|---|---|---|

| 1 | 24/8/2019 | One day workshop on Optimization techniques |

| 2 | 11/1/2019 | Go Karting Championship |

| 3 | 16/8/18 | One day workshop on Optimization technique |

| 4 | 28/5/18 | Faculty development programme on Design of machine elements |

| 5 | 2/3/18 | Kings Moto Championship |

| 6 | 20/11/17 | Faculty development programme on Thermal Engineering |

| 7 | 22/9/17 | National level workshop on Lean Six Sigma |

| 8 | 24/8/17 | One day workshop on Optimization technique |

| 9 | 25/10/17 | Two day workshop on Autodesk 360 Fusion |

| 10 | 23/2/18 | One day workshop on Frame design and motion analysis |

| 11 | 15/9/16 | Guest lecture: Engineers day |

| 12 | 17/8/16 | One day workshop on Optimization technique |

| 13 | 3/9/16 | Guest lecture: Advance Industrial process |

| 14 | 13/8/16 | ISME student chapter Inauguration and Guest lecture on Advance processes in India |

| 15 | 5/8/15 | One day carrier oriented workshop on hands-on training in NDT |

| 16 | 8/3/16 | Guest Lecture on Recent trends in Manufacturing |

| 17 | 12/8/14 | Hands on Training using Mini Tab Software |

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Duanamics Machines International Pvt Ltd

2.16 LPA

Duanamics Machines International Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Wipro Infrastructure Pvt Ltd

1.8 LPA

Wipro Infrastructure Pvt Ltd

Delphi TVS

2.04 LPA

Delphi TVS

Delphi TVS

2.04 LPA

Delphi TVS

Industrial Metrological Centre

2.5 LPA

Industrial Metrological Centre

Industrial Metrological Centre

2.5 LPA

Industrial Metrological Centre

Preludesys.

3.60 PA

Preludesys.

Sutherland

2.16 LPA

Sutherland

Joy Technology

1.92 LPA

Joy Technology

National Plastic Technology

1.2 LPA

National Plastic Technology

National Plastic Technology

1.2 LPA

National Plastic Technology

National Plastic Technology

1.2 LPA

National Plastic Technology

Q Spider

2.52 LPA

Q Spider

Our Recruiters

|  |  |

|  |  |

|  |  |

|  |

| Faculty Name | Research Title | Year | ISSN/DOI |

|---|---|---|---|

| Dr.Harikrishnan | Experimental investigation of parallel type - evacuated tube solar collector using nanofluids, Taylor and Francis,ENERGY SOURCES, PART A: RECOVERY, UTILIZATION, AND ENVIRONMENTAL EFFECTS | 2020-21 | Online ISSN: 1556-7230 |

| Dr. BabuSasi Kumar | Experimental investigation of parallel type - evacuated tube solar collector using nanofluids, Taylor and Francis,ENERGY SOURCES, PART A: RECOVERY, UTILIZATION, AND ENVIRONMENTAL EFFECTS | 2020-21 | Online ISSN: 1556-7230 |

| T.Kanagaraju | Effect of cryogenic and wet coolant performance on drilling of super duplex stainless steel (2507) | 2020-21 | doi:10.1166/mex.2019.1613 |

| Mr.K.Nimel Ross | Investigation of surface modification and tool wear on milling Nimonic 80A under hybrid lubrication is published in Tribology International. (Elsevier-IF- 4.27), 2020 | 2020 - 21 | |

| Applying visualization techniques to study the fluid flow pattern and the particle distribution in the casting of metal matrix composites” is published in Journal of Manufacturing Processes. (Elsevier-IF- 4.17), 2020 | 2020 - 21 | ||

| Machining Investigation of Nimonic‑80A Superalloy Under Cryogenic CO2 as Coolant Using PVD‑TiAlN/TiN Coated Tool at 45° Nozzle Angle” published in Arabian journal of science and Engineering. (Springer-IF- 1.72), 2020 | 2020 - 21 | ||

| Multi-response optimization of Ti-6Al-4V milling using AlCrN/TiAlN coated tool under cryogenic cooling” published in Journal of production systems and Manufacturing sciences. (Imperial Open), 2020 | 2020 - 21 | ||

| Experimental investigation of Mechanical properties in friction welding parameters for dis-similar metals (SS-304 & SS-410)” published in Materials today Proceedings. (Elsevier), 2020 | 2020 - 21 |

| Faculty Name | Book/Journal Title | Research Chapter/Topic | Institution | Publisher |

|---|---|---|---|---|

| Dr.S.Harikrishnan | Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications | Nanomaterials for Latent Thermal Energy Storage | Springer | |

| Dr.S.Harikrishnan | Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications | Nanomaterials for Latent Thermal Energy Storage | Springer | |

| Dr. Muniaraj | EFFECT OF CUTTING PARAMETERS ON | Kings Engineering College | Elsevier | |

| Dr. Muniaraj | SURFACE ROUGHNESS IN DRILLING OF | Kings Engineering College | Elsevier | |

| Dr. Muniaraj | AL-SIC-GR COMPOSITES USING RSM AND | Kings Engineering College | Elsevier | |

| Dr. Muniaraj | FUZZYLOGIC MODELING METHOD | Kings Engineering College | Elsevier |

| S.No | Company Name | Address | Date/Year of Signing MOU | Duration |

|---|---|---|---|---|

| 1 | AES Automotive Company Private Limited | 27/1-D, Jothi Nagar, Periyapanicherry Road, Paraniputhur, Mangadu Main road,Chennai - 600 122, Tamil Nadu, India | 12 th August 20142014-15 | 2 Years |

| 2 | Arrow Machine Tools | New No.18,Old No.1, Balaji Nagar,Ambattur, Chennai- 600 053, Tamil Nadu, India | 10 th February 20152014-15 | 2 Years |

| 3 | Ceecons Process Technologies Private Limited | SP-66, XVII phase, Ambattur Industrial Estate, Ambattur, Chennai 600 058. Tamil Nadu, India | 15 th October 2014 2014-15 | 3 Years |

| 4 | Design CAD Technologies | No. 3/ 1319, Bharathiyar Nagar, 6th street, O.M.R., Mettukuppam, Chennai-97. | 19th March 2015 2014-15 | 3 Years |

| 5 | Dynatherm Alloys Private Limited | No.7, Kamala Nagar,Sholinganallur, Chennai – 600 119 | 15th March 2017 2016-17 | 2 Years |

| 6 | IP Rings (P)Ltd | D11/12 Industrial Estate, Maraimalai Nagar-603 209, Kancheepuram District,Tamil Nadu, India | 25th April 2017 2016-17 | 2 Years |

| 7 | Kerith Technical Services, | No:72/28, Dr.Moorthy Nagar Main road, Padi, Chennai -600 050, Tamil Nadu, India | 6th June2018 2017-18 | 2 Years |

| 8 | Precision Machines & Auto Components (P) Ltd | No.25 & 26, Mount Poonamallee Road, Nandambakkam, Chennai – 600 089. | 8th August 2018 2017-18 | 2 Years |

| 9 | Trinity Institute of NDT Technology | Trinity NDT 'Aspire', #491, Site No.12,4th Phase, 2nd Stage, Peenya Industrial Area, Bangalore – 560 058, India | 13 th February 2019 2018-19 | 2 Years |

| 10 | TWG Group of Training & Certification | No:6 Boopathy Street, Virugampakam,Chennai – 600 092,Tamil Nadu, India | 15th March 2109 2018-19 | 2 Years |

In our department, there are sophisticated equipment in Manufacturing Technology Lab where, the scholars/researchers could be permitted to utilize the facility. Also, In the department there are potential and competent doctorates working in the fields of Manufacturing, Thermal and Materials Science. They provide fruitful suggestions and guidance to the research scholars.